About us

.

RONA has a strong export position, qualified personnel and the most modern technologies. The glassworks in Lednicke Rovne is one of the world leaders in the processing of lead-free beverage glass known as crystalline.

The glassworks is trading with a wide range of customers from all over the world and provides them with activities related to the development, production and servicing of beverage glass for households, hotels and restaurants as well as for the airlines and shipping companies. Machine and handcrafted goblets and beverage glasses are covering the basic position in the company’s product range.

96% of production is exported and is available in more than 80 countries worldwide.

The yearly production of the company exceeds 60 million pieces.

Products of the company can be found at Buckingham palace and the White House.

The glass from Lednické Rovne can be found in the New York Rockefeller center’s Rainbow Room, and in luxury hotels in Dubai and Las Vegas.

The glass from the RONA company is supplied to airlines including: Emirates, Etihad, KLM, and American Airlines.

.

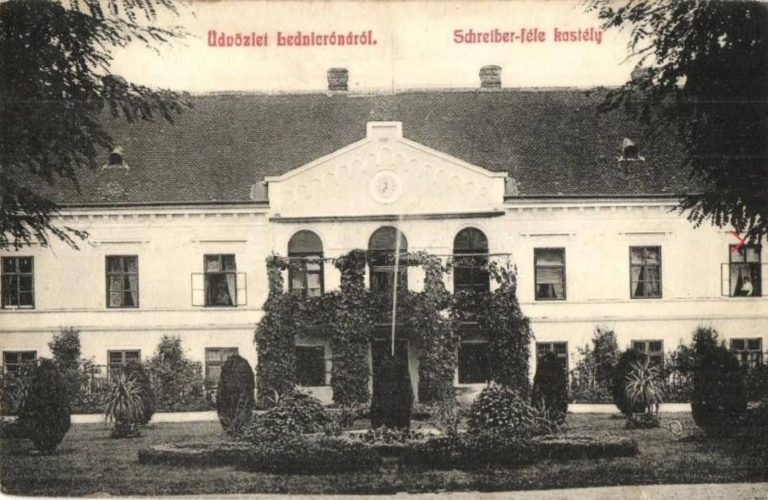

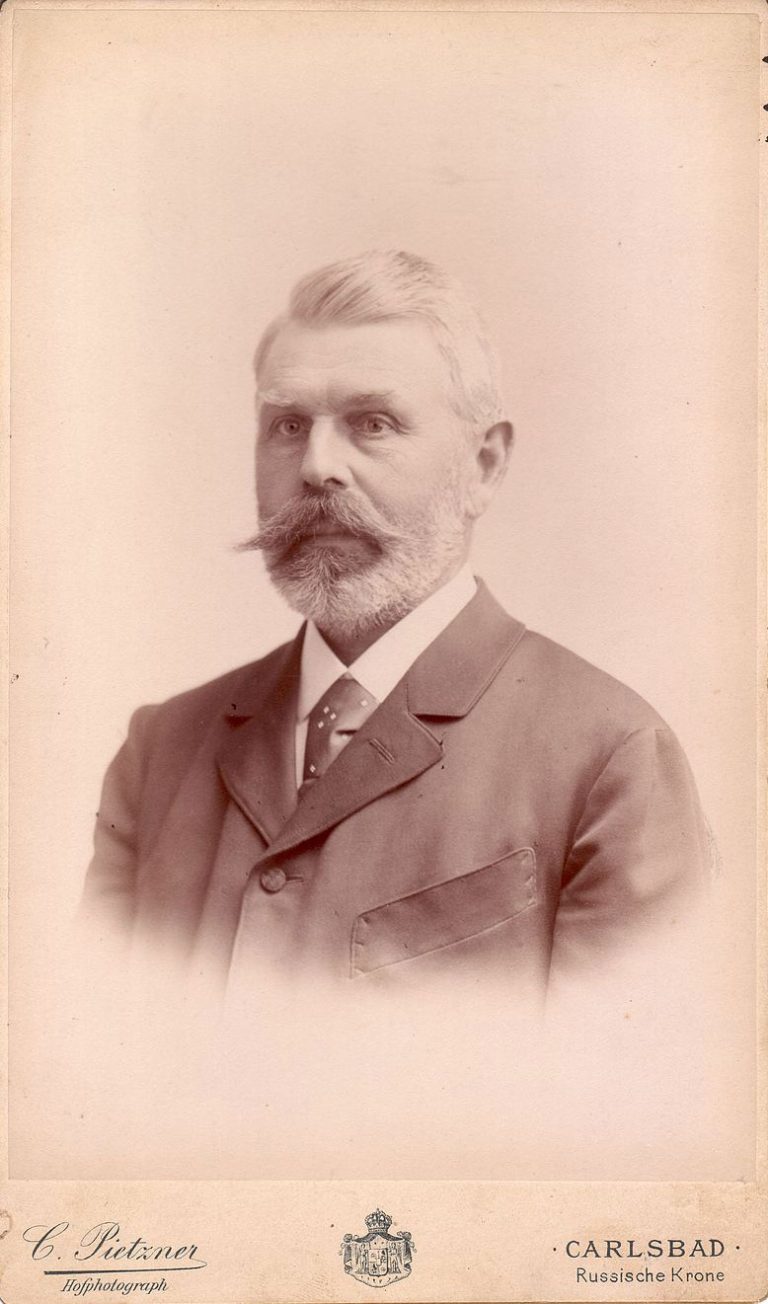

The glassworks was founded in 1892 by the entrepreneur Jozef Schreiber as the last and the largest glassworks of the Viennas company Schreiber und Neffen, which had the most modern technical equipment for its time. The glassworks in Lednicke Rovne is the most successful Slovak glassworks in history.

In 1896, the Lednicke Rovne-based glassworks introduced pantographs of the English production as the first on the continent. In the 1940s, the glassworks cooperated with professional artists Vincent Hložník and Martin Benko in creation of the decors.

The production range of the glassworks was very wide and diverse from the beginning. It contained historicizing, often richly decorated pieces, while in the era of Functionalism, simple elegant cups and shapes were developed, predominantly made of clear smooth glass, which were in full compliance with the principles of this minimalist style.

These lines have been further emphasized and developed by patenting of a new handmade technology, the so-called pulled stem in 1956, which is still one of the iconic signs of glass products from Lednicke Rovne.